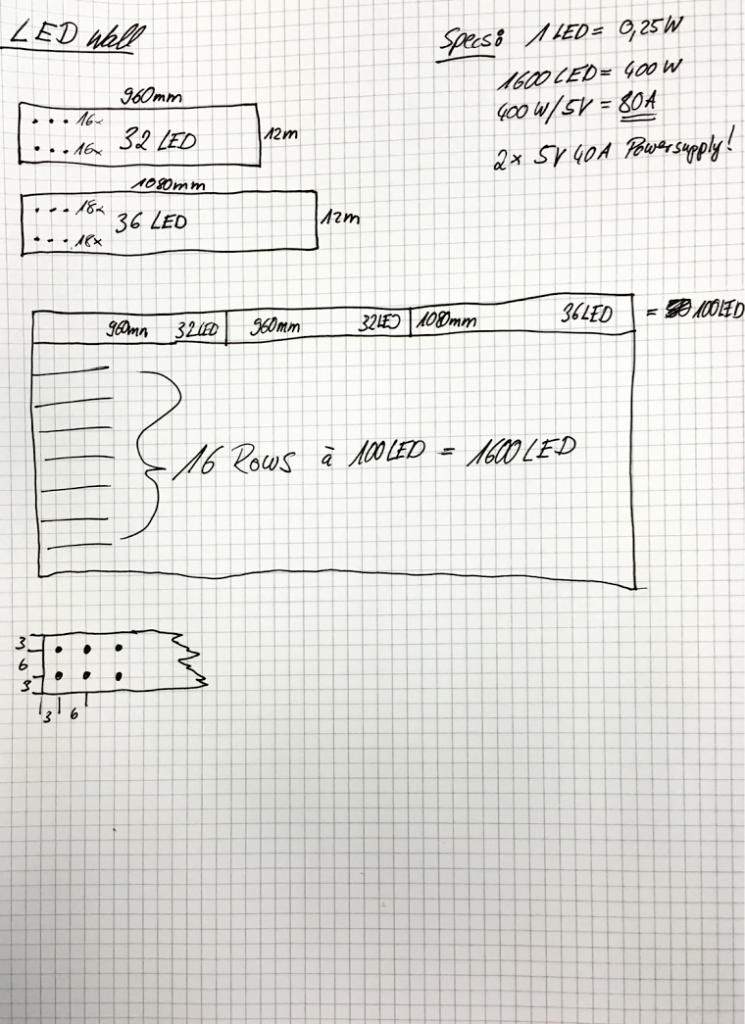

Outtakes

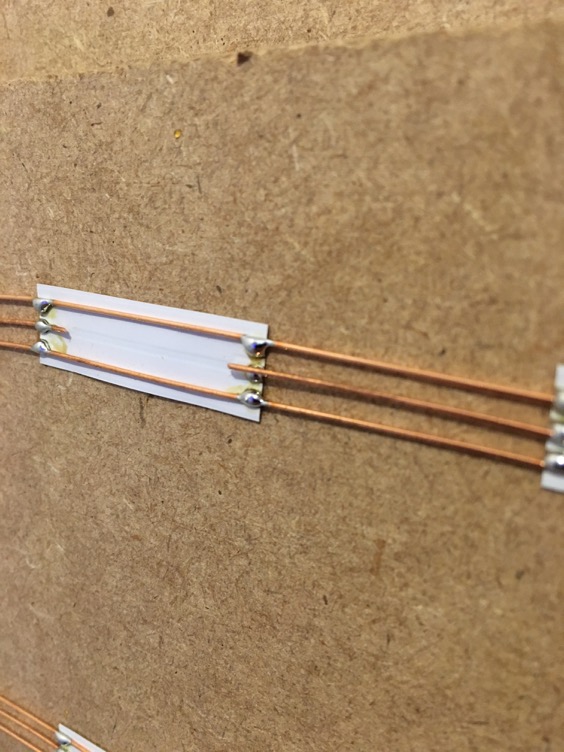

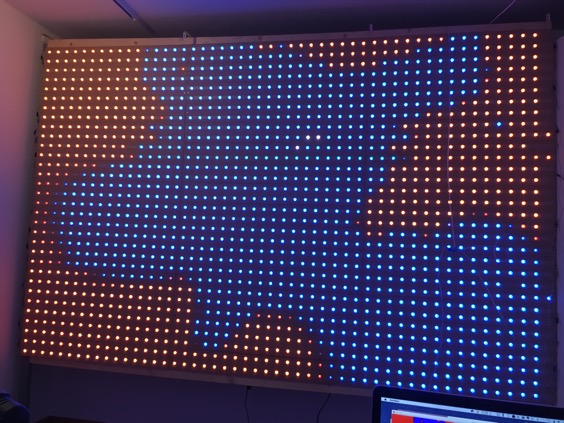

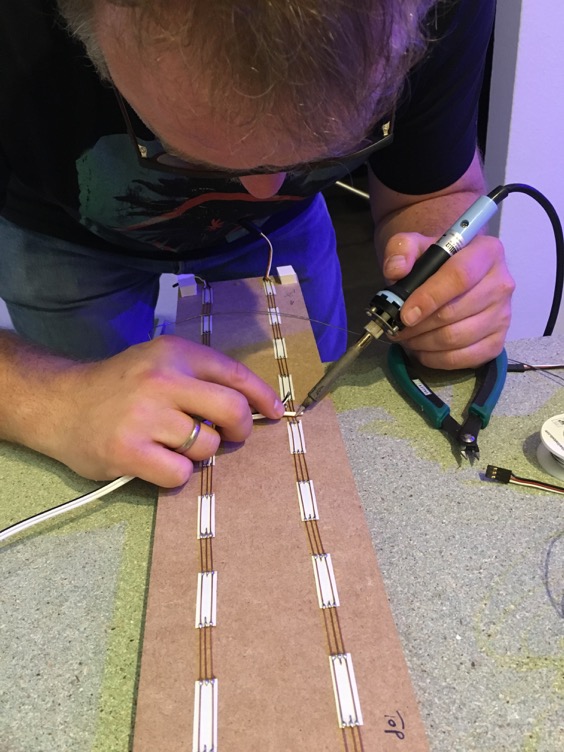

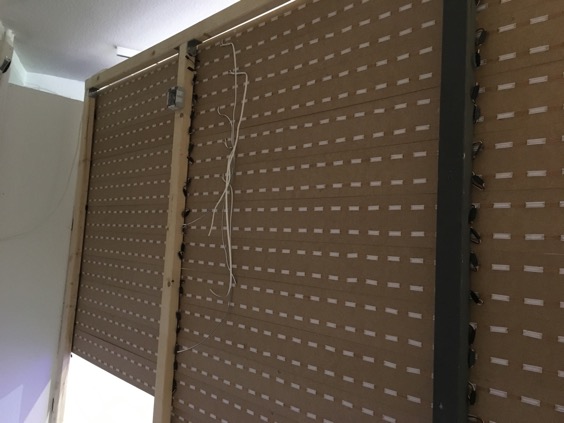

Beside some minor soldering issues and a defective connector most of the wall is working. After replacing two defective LED’s and one defective connector a failing row drove me crazy. As you can see in the picture below I forgot to solder one wire. This causes a whole row not working. This was sporadic. Then I found it: